By Shahab Khokhar

Robotics is booming, and the numbers prove it. By 2025, the market is set to hit $50.8B, with service robots leading the charge at $40.58B. Growth isn’t slowing down either—by 2029, the industry is expected to soar past $73B (Statista).

What’s Driving this Surge?

✅ Labor shortages

✅ An aging population

✅ GDP growth & inflation

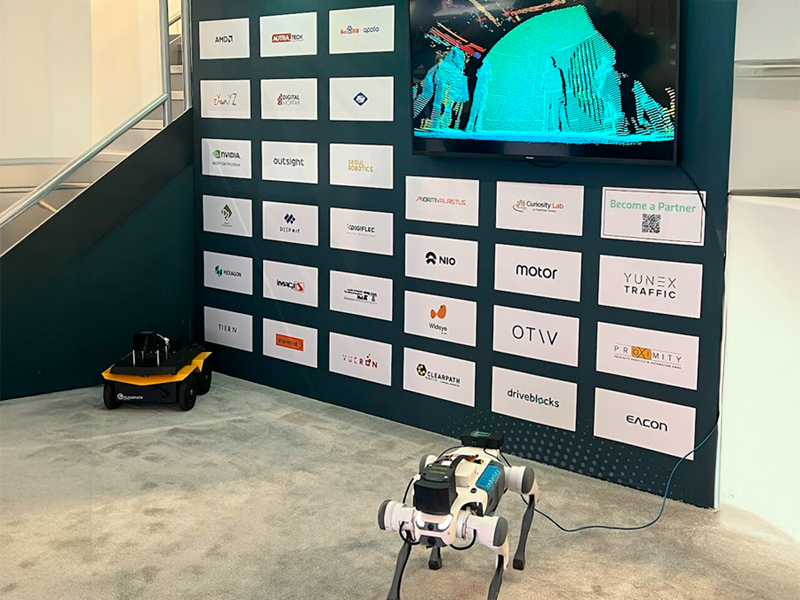

As more robots hit the market, better vision technology is a must. While cameras have played a role, LiDAR has become the go-to solution for navigation, object detection, and decision-making. Seyond is at the forefront with directional LiDAR solutions like Robin W and Robin E1X, offering key advantages over traditional rotating LiDAR.

Understanding the Difference

- Directional LiDAR – Uses techniques like polygon, galvo or microelectromechanical systems (MEMS) to direct laser beams. With Seyond’s directional LiDAR, the moving parts are passive.

- Rotating LiDAR – Uses a spinning mechanism to emit laser beams in a 360-degree sweep. Rotational LiDAR’s moving parts are active, requiring rotation coupling that is fragile and expensive.

While rotating LiDAR still serves niche applications, directional LiDAR is emerging as the superior choice for modern robotics. Five key benefits include:

1. Enhanced Accuracy & Resolution

By focusing laser beams in specific directions, directional LiDAR delivers sharper, more detailed data than rotational lidar, making robots smarter and more precise.

🔍 Seyond’s Robin W achieves 0.15°H × 0.36°V resolution and captures 1.28M+ points per second, enabling superior perception and control.

🚀 Autonomous Navigation – Dense point clouds ensure precise path planning, obstacle avoidance, and smooth maneuvering.

🤖 Object Recognition & Manipulation – High-resolution 3D modeling enhances detection for picking, sorting, and inspecting objects.

🌍 Mapping & Surveying – Detailed 3D maps aid in exploration, construction, and infrastructure inspection.

With directional LiDAR, robots can see, think, and move better than ever. 🔍✨

2. Reduced Data Processing

Traditional 360-degree LiDAR captures excessive, often unnecessary data, slowing processing and delaying decision-making. Directional LiDAR eliminates the clutter, focusing only on key areas for:

🚀 Faster Processing – Less data means quicker reactions and real-time decision-making.

🔧 Greater Efficiency – Less computational load means more effective and sustainable robots.

Why process what you don’t need? Directional LiDAR keeps robots agile and responsive.

3. Power Efficiency That Keeps Robots Running

Directional LiDAR, with no rotation and fewer moving parts, consumes far less power than traditional rotating LiDAR.

🔋 Less Power, More Runtime: Seyond’s Robin W LiDAR operates at under 9W, maximizing battery life for mobile robots.

Rotating LiDAR? Constant motion drains energy, making it unsuitable for battery-powered robots, small drones, and compact autonomous systems.

Why waste power when you don’t have to?

4. Smaller, Smarter, More Affordable

🚀 Compact & Easy to Integrate – Without bulky mechanics, directional LiDAR fits seamlessly into any robotic platform.

🔧 Space-Saving & Flexible – No raised mounts or excess weight—just smart integration where it matters.

💰 Cost-Effective – A simpler design means lower production costs, making advanced LiDAR more accessible.

Meanwhile, rotating LiDAR is bulky and heavy, taking up valuable space on robots. Why go big when you can go smart?

5. Reliability & Durability

With only passive moving parts, directional LiDAR is:

✅ More Reliable – Less wear and tear means lower maintenance costs and longer operational life. This is in contrast to rotational lidar, which contains active moving parts and requires rotation coupling, which is fragile and expensive.

🛡️ More Durable – Resistant to shock, vibration, and extreme temperatures.

💡 Seyond’s Robin W boasts IP67 (body) and IP69K (window) ratings, proving its ruggedness in harsh environments.

Compare that to rotating LiDAR, which spins 300+ million times a year, wearing out fast and demanding constant upkeep.

The Future of Robotics Runs on Directional LiDAR

As robotics evolves, the need for efficient, compact, and real-time sensors is skyrocketing.

While rotating LiDAR still has niche applications, directional LiDAR is driving the next wave of innovation—powering autonomous navigation, precision manipulation, and wearable systems.

🚀 The shift is clear: for cutting-edge robotics, directional LiDAR is the future.