Future Proof your LiDAR deployment

Introduction

LiDAR (Light Detection and Ranging) technology has revolutionized how we perceive and interact with our environment. By emitting laser beams and measuring their reflections to determine distance, LiDAR is essential in various industries, including autonomous vehicles, intelligent transportation systems and robotics. Two prominent types of LiDAR are rotational and directional systems.

Rotational LiDAR

Rotational LiDAR are perhaps the most recognized type due to their widespread application in early autonomous vehicle prototypes. These systems operate by continuously spinning a laser beam around a vertical axis, thereby creating a 360-degree field of view. Each laser pulse maps a point in the surrounding environment, allowing for comprehensive 3D mapping. The main advantage of rotational LiDAR is its wide field of view.

However, rotational LiDAR systems are often bulky and mechanically complex. The moving parts can be prone to wear and tear, which may affect reliability over time. Additionally, they tend to consume more power and can be costlier to maintain and repair.

Directional LiDAR

In contrast, directional LiDAR are designed to focus on specific areas rather than providing a full 360-degree view. They use a targeted beam approach, scanning designated zones or points of interest. This targeted design allows these sensors to deliver higher resolution and precision within the chosen area, making them well-suited for applications requiring detailed focus and accurate measurements.

The increasing span of LiDAR:

LiDAR were initially deployed on vehicles. However, the last few years have seen adoption of LiDAR in many distinct verticals including robotics, ports, smart cities, intelligent traffic management and railroads.

The mass adoption of LiDAR has been challenged by high cost and maintenance needs of rotating LiDAR. With the recent technology breakthroughs, the cost of directional LiDAR has gone down while the performance has improved.

Advantages of Directional LiDAR:

One significant advantage of directional LiDAR is lower power consumption. By focusing energy on specific areas rather than rotating to cover an entire environment, directional LiDAR can operate more efficiently and extend battery life in portable systems. This makes them particularly advantageous for applications in robotics, drones, and certain industrial contexts where energy efficiency is crucial.

While rotational LiDAR offer 360-degree horizontal coverage, directional LiDAR come with several distinct advantages.

Directional sensors excel in scenarios requiring precision and integration into space-constrained environments. Their compact size makes them easier to fit into small spaces, a crucial consideration for industries developing compact autonomous robots or consumer electronics.

Lastly, the ability to focus on specific regions without unnecessary data from other areas minimizes processing requirements and enhances the speed and efficiency of data interpretation.

Applications Where Directional LiDAR Excels:

Directional LiDAR’s strengths make it particularly valuable in certain sectors:

1. Automotive Industry: In autonomous vehicles, directional LiDAR can be focused on critical zones, such as directly in front of the car or at intersections, providing vital information for navigation and safety without unnecessary data overload.

2. Robotics: For robotics, where agility and precision are paramount, directional LiDAR systems offer the accuracy needed for intricate tasks such as navigating the robot in a challenging environment.

3. Intelligent Traffic Systems: Directional LiDAR are ideal for traffic applications like monitoring intersections, highways, crossings etc. These applications require the LiDAR to focus on a particular area and directional LiDAR excel at this.

Futureproof your LiDAR deployment:

While rotational LiDAR were the pioneers in the 3D LiDAR industry, most, if not all, manufacturers are moving towards solid state like directional LiDAR.

There are many reasons for this shift:

- Directional LiDAR have fewer parts and are better suited for automated mass production

- With fewer parts and no 360-degree rotation, the directional LiDAR are less prone to wear and tear and performance degradation

- Mass production of directional LiDAR with minimal moving pieces reduces the cost significantly

- Adoption of directional LiDAR in smart phones and other applications ensures cost of parts will continue to go down

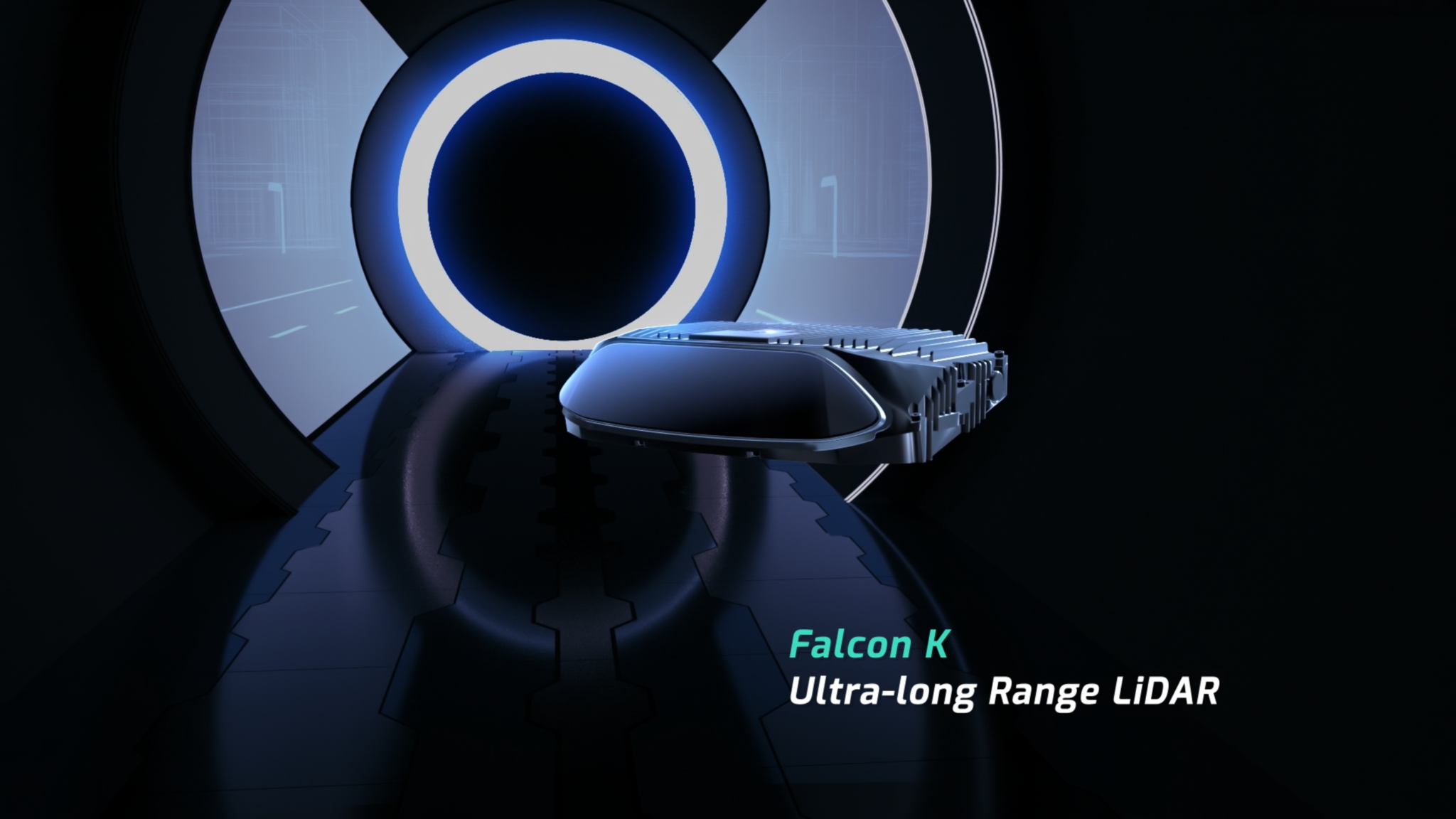

To learn more about Seyond’s directional sensors, including the Falcon K and Robin W, visit us HERE

Contact us HERE